In 2022/23, I led the design of a SaaS solution for supply chain management, focusing on optimizing the interaction between repair centers, the supply chain team, and customer service.

Manual processes in managing repair center information caused inefficiencies and errors, negatively impacting customer service quality and operational efficiency.

Context:

The Supply Chain (SC) team manually managed all their operations, relying heavily on emails, phone calls, and weekly updates to an Excel file. This process was not only inefficient and prone to errors but also led to duplicated work.

On the other hand, the Customer Service (CS) team faced challenges when searching for the nearest repair centers for customers, as there was no integration within the SaaS platform (Icon), which delayed their workflow.

Main problem:

The lack of automation and centralized information created inefficiencies, errors, and delays in communication between the Supply Chain, Customer Service, and Repair Center teams.

Objective:

Design and implement a solution that would automate workflows, reduce operational time, and centralize information into an integrated system accessible to all teams.

Responsibilities:

Create a detailed roadmap to deliver the first MVP.

Conduct in-depth research with the involved teams (SC, CS, and Repair Centers).

Design a user-centered solution to address the main pain points.

Research:

Interviews with the Supply Chain (SC) team:

I identified that the manual process of updating the Excel file was error-prone and time-consuming.Shadowing the Customer Service (CS) team:

I observed that the lack of integration in the SaaS platform caused delays in searching for repair center information.Interviews with Repair Centers:

I discovered there was no standardized flow for communicating changes in pricing, schedules, and availability.

Design and development:

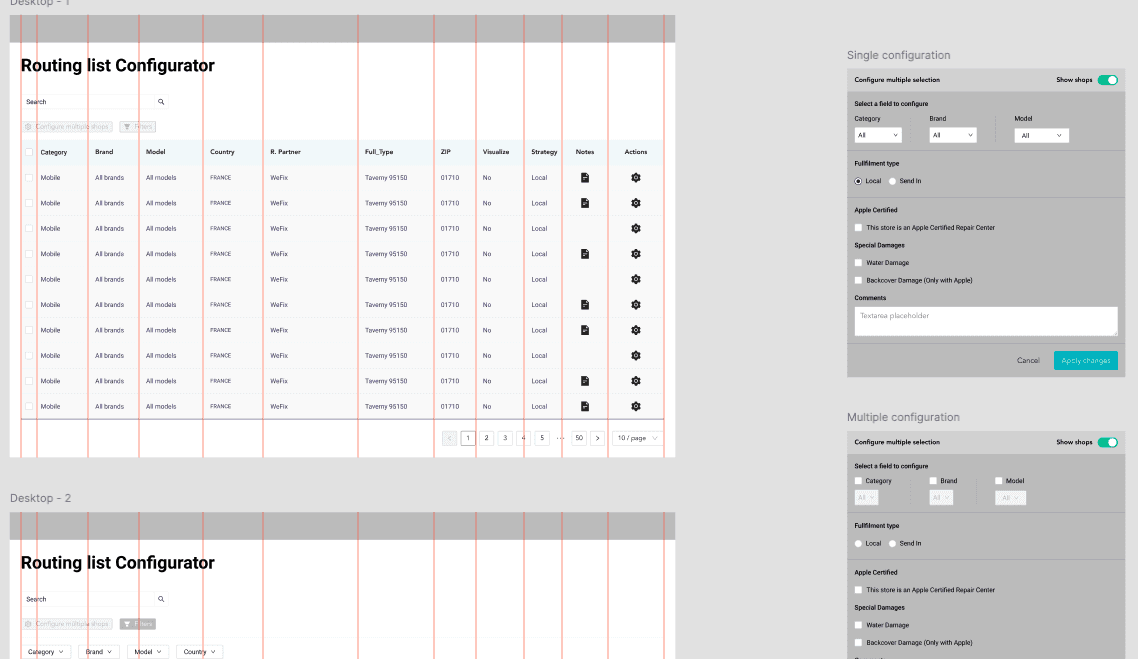

For the Supply Chain (SC) team:

I designed a SaaS system that automated data import from the Excel file, enabling critical actions such as opening/closing stores, editing information, and selecting the best options based on updated pricing.For Repair Centers:

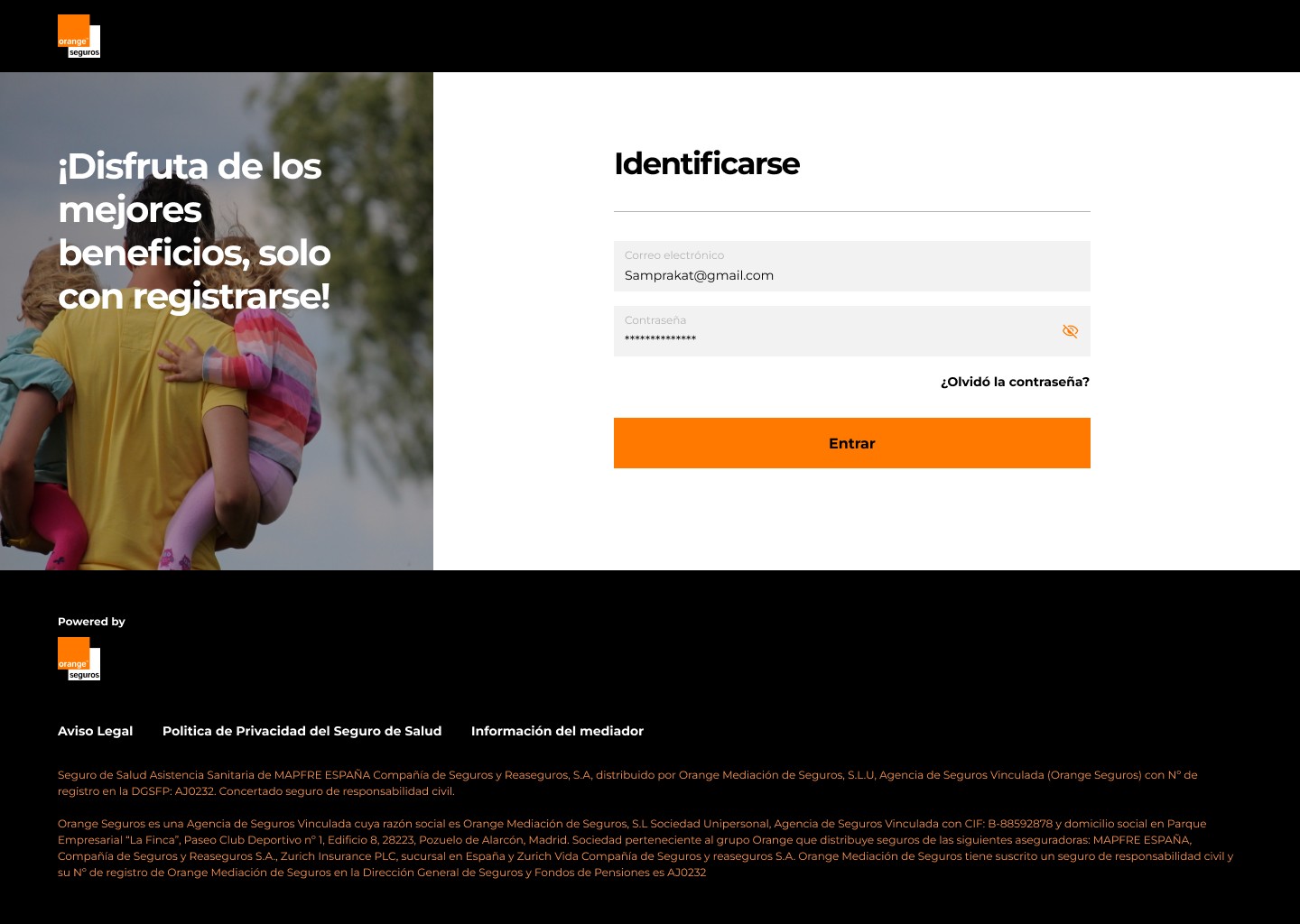

I created a connected client within the SaaS system, allowing centers to upload a weekly JSON file with updated information.For the Customer Service (CS) team:

I integrated a new feature into the SaaS platform (Icon) that allowed CS to search for the nearest repair centers directly within the system, eliminating reliance on the external Excel file.

Quantifiable impact:

40% increase in operational efficiency, eliminating the chaos of manual data entry.

Significant reduction in search times for the Customer Service team, improving customer interactions.

Scalable and modular system, ready for continuous improvements and optimized loading times.

Qualitative impact:

Greater autonomy for Repair Centers, while maintaining full connectivity with the Supply Chain team.

Improved collaboration between teams, eliminating communication inconsistencies.

Key learnings:

Interdisciplinary collaboration was essential to gain a comprehensive understanding of the problem and design a versatile solution.

Using Bolttech’s design system ensured a consistent and functional user experience.

The system’s scalability highlighted the importance of building solutions that evolve with business and user needs.